CONTENTS

PART: 1 The Impact of Microorganisms in Pharmaceutical and Medical Device Manufacture

The Essentials of Pharmaceutical Microbiology

by Tim Sandle and Madhu Raju Saghee

Introduction

History of Microbiology

Fundamental Characteristics of Microorganisms

Bacteria

Fungi

Protozoa

Algae

Viruses

Microbial Taxonomy

Microbial Growth

Microbiological Culture Media

Identification and Characterization of Microorganisms

Types of Bacteria

Overview of Pharmaceutical Microbiology

The Scope of Pharmaceutical Microbiology

Product Related Testing Regimes

Starting Materials

In-Process Samples / Intermediate Product

Final Product Formulations

Finished Product

Testing of Utilities

Environmental Monitoring

The Application of Pharmaceutical Microbiology

Counting

Sampling

Microorganisms Detected From Pharmaceutical Manufacturing Environments

Contamination Control

Other Microbiology Laboratory Tests

Microbial Identification

Water Activity

Disinfectant Efficacy Testing

Antimicrobial Susceptibility Testing

Microbial Immersion Studies

Cleaning Validation Studies

Investigation of Out of Limits and Out of Trend Results

Microorganisms Used In Pharmaceutical Microbiology Laboratories

Other Activities

Conclusion

References

Relevance of Microorganisms in Pharmaceutical Processing

by Ossama M. El-Tayeb

Introduction

Historical Review of the Involvement of Microbiology with Pharmaceutical Practice

Implications of aseptic surgery, personal and public hygiene

Implications of Food Microbiology

Implications of the introduction of parenteral therapy: {earliest procedures for

sterilization and preservation}

Early tests for sterility: influence of diagnostic medical microbiology

Early pharmacopoeial guidance on sterilization and sterility testing

Historical Review of Science-Based Pharmaceutical Sterilization and Microbiological Quality Control

Re-definition of the pathogenicity of microorganisms

Contributions of the study of microbial injury and death

Contributions of the food processing technologies: the over-kill approach to sterilization

Contributions of the aerospace and electronics industries.

Hospital sterilization and Central Sterile Supply vs. on site sterilization

Impacts of material sciences and development of cold sterilization methods

Filtration as a breakthrough and the bio-burden approach to sterilization.

Impact of statistical fallacies in sterility testing and population death kinetics.

The Broader Picture of Microorganisms and Pharmaceutical Manufacturing: Challenges, Solutions and Pharmacopoeial Guidance

Microorganisms and Ophthalmic Dosage Forms

Microorganisms and Oral Dosage Forms

Microorganisms and Topical Dosage Forms

Microbiological Challenges, Solutions and Pharmacopoeial Requirements

Current Pharmacopoeial Guidance

The Fundamental Concepts

Sampling for Microbial Quality Control and the Microbiologically Homogenous

Batch

Quality Assurance as an Essential Element in Microbial Quality

The Roles of the Microbial Quality Control Laboratory

Current Pharmacopoeial Guidance {on sterilization, sterility testing and microbial

quality of non-sterile dosage forms}

The Future

Will all Pharmaceuticals be Aseptically Processed?

The future of the Microbiological Quality Control Tests

References

Microbial Contamination and Spoilage

by David G. Allison

Introduction

Sources of Microbial Contaminants

Raw Materials

Materials of Natural Origin

Microorganisms from Plant Material

Microorganisms from Animal Sources

Microorganisms from Mineral-Derived Materials

Synthetic Raw Materials

Water

Types of Water

Disinfection of Water

Microbial Contamination from the Manufacturing Environment

Air supply

Equipment and facilities

Personnel

Users / consumers

Factors affecting Microbial Spoilage of Pharmaceutical Products

Preparation and Storage

Nature of the Contaminant Inoculum

Moisture Content

Nutritional Factors

pH and Redox

Consequences of Microbial Growth

Microbiological Control of Raw Materials

Summary

References

Microbiological Considerations in Medical Device Industry

by Martell Winters

Introduction

The Medical Device Microbiology Life Cycle

Inherent and Accumulated Microbial Contamination

Product Design Microbiology

Raw Material and Component Microbiology

Shipping and Storage of Raw Materials and Components

Environmental Microbiology

Product Assembly Microbiology

Cleaning of Products

Packaging Process Microbiology

Sterilization Process Microbiology

Product Use Microbiology

Medical Device Microbiological Contamination

Controlling Product Bioburden

Aseptic Technique

No Magic Answers for Bioburden Control

Use of Bioburden Testing to Improve Manufacturing Microbiology

Use of Sterility Testing to Improve Manufacturing Microbiology

Microorganisms of Concern

Microbiological Challenges for Products with Tissue Components

References

PART: 2 Aspects of Microbiological Quality Control

Selection of Microbiological Culture Media and Testing Regimes

by Tim Sandle

Introduction

Types of Culture Media

Media Manufacture

Quality Control of Culture Media Supplier

When to Perform Quality Control?

Establishing a Nutritive Properties Testing System

Micro-organisms: Typed Cultures

Micro-organisms: Environmental Isolates or ‘Wildtypes’

Micro-organisms: The Microbial Challenge

Micro-organisms for the Testing of Selective Media or Differential Media

Test Method

Test Regime

Sterility Test of Media

Expiry Time Assessment of Culture Media

New Lots of Media

Media Release and Quarantine

Conclusion

References

Microbial Identification

by Ziva Abraham

Importance of Microbial Identification

Isolation of Microorganisms

Staining Methods

Gram Staining

Spore Stain

Fluorescent Stains

India Ink (Colloidal Carbon) Stain

Acid-Fast (Ziehl Neelsen) Stain

Lactophenol Cotton Blue Stain

Microscopy

Stereo Microscope

Bright Field Microscopy

Dark Field Viewing

Phase Contrast Microscopy

Differential Interference Contrast (DIC) Microscopy

Florescent Microscopy

Pre-Differentiation or Confirmation

Taxonomy, Classification, Identification and Nomenclature

Phenotypic Microbial Identification Systems

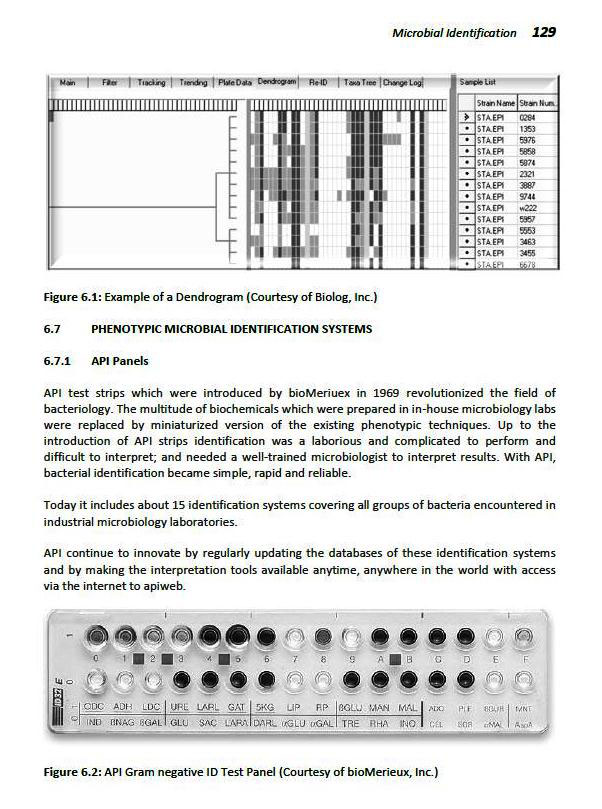

API Panels

Automation in Microbial Identification

Vitek® Microbial Identification Systems

BiologTM System

MIDI Sherlock® Microbial Identification System using Fatty Acid Methyl Ester

(FAME) Analysis

Genotypic Systems

Polymerase Chain Reaction (PCR)

DiversiLab® Strain Typing

Microarrays in Microbial Identification

Fungal Identification

Conclusion

Acknowledgements

References

Microbial Examination of Non-sterile Products

by Jaymie Tomes and Florence Wu

Introduction

The Limitations and Values of Microbial Enumeration Tests

Product Sampling for Microbial Examination

Sampling Schemes

Sample Sizes

Sample Preparation

Media Growth Promotion Test

Method Suitability Test

Enumeration Methods

Media and Incubation

Colony Counting and Interpretation of the Results

Tests for Specified Microorganisms

Staphylococcus aureus

Pseudomonas aeruginosa

Escherichia coli

Salmonella

Clostridium

Candida albicans

Bile Tolerant Gram Negative

Setting Microbial Limits for Non-Sterile Pharmaceuticals and Raw Materials

Conclusions

References

Practical Approaches to Sterility Testing

by Tim Sandle

Introduction

The Sterility Test

Sterility Test Method Validation

Validation of Culture Media

Sterility Test Validation

Dealing with ‘Difficult’ Products

Membrane Filtration

Type of Membrane Filter

Type and Number of Rinse Solutions

Direct Inoculation

Type of Neutralising Agent

Dilution

Turbid Samples

Antibiotics

Oily Samples

Anti-cancer Treatments

Implants

Sterile Aerosols

Cell Lines

Fibrin Sealant

Questions relating to validation that are not directly answered by the Pharmacopoeias

The Stasis Test

Training Programme

Validation Documentation

Validation Protocol

Validation Report

Summary

References

Microbial Aspects in Cleaning Validation

by Andrew Walsh

Introduction

Regulatory Aspects of Cleaning

API Manufacturing

Finished Pharmaceuticals

Cleaning Processes

Cleaning Agents

Cleaning Procedures

Manual Cleaning

Clean-Out of-Place (COP)

Clean-in-Place (CIP)

Solid Dosage Forms

Setting Microbial Acceptance Criteria for Solid Dosage Forms

Semi-solid Dosage Forms

Setting Microbial Acceptance Criteria for Semi-solid Dosage Forms

Hold Time Studies

Microbial Testing in Cleaning Validation

Conclusion

Acknowledgements

References

Validation of Microbiological Methods

by Sandy Rubio

Introduction

Scope

Why is Bioburden Testing Important?

Strategy for Validation

Protocol Considerations

Description of Product

Manufacturing Process

Challenge Microorganisms

Current Validation Status

Regulatory and Guidance Documents

General Protocol Considerations

Bacteriostasis/Fungistasis Evaluation

Acceptance Criteria

Method Development

Sample Hold Time Determination

Maintaining Status of Validated Methods

Case Study

Background

Review Findings

Conclusion

References

Selection and Validation of Disinfectants

by Paul Viña, Sandy Rubio and Tim Sandle

Introduction

Types of Disinfectants

Non-Oxidizing Disinfectants

Alcohols

Aldehydes

Amphoterics

Acid Anionics

Biguanides

Phenolics

Quaternary Ammonium Compounds (QACs)

Oxidizing Disinfectants

Halogens

Oxidizing Agents

Selection of Disinfectants

Number, Type, and Location of Microorganisms

Number

Type of Microorganism and Disinfectant Resistance

Location of Microorganisms

Concentration

Time

Temperature and pH

Interfering Substances

Validation of Disinfectants

Test Methods

Basic Suspension Test

Bactericidal Suspension Test and Fungicidal Suspension Test

Surface Test

Test Variables

Challenge Microorganism Selection and Inoculation of Surface Materials

Selection of Test Surfaces

Disinfectant Test Concentration and Preparation

Establishing the Disinfectant Expiration Date

Evaluating Interference from Organic Material

Application of Disinfectant to Surface Coupons

Contact Time

Selection of Neutralizing Agents

Continued Evaluation of Disinfectant Effectiveness

Conclusion

References

Further Reading

Auditing a QC Microbiology Laboratory

by Andy Martin

Introduction

What is an Audit and Why Should They be Performed

General Principles of the Audit Process

Auditing the QC Microbiology Laboratory, What to Look For

Strategy for Microbiological Control

Sample Receipt

Product Sample Testing

Bacterial Endotoxin Testing

Media Control and Testing

Incubator, Refrigerator and Freezer Control and Monitoring

Culture Collections

Water Testing and Water System Monitoring

Environmental Monitoring

Isolate Identification, Gram stain techniques and ID system validation

Autoclave control

Antibiotic assays and Preservative testing

Sterilization, Cleaning and disinfection validation efficacy

Microbiological Training of Laboratory and Production Staff

Validation of Holding Times

Atypical Results and Out Of Specification Procedures

Auditing Techniques to Get the Most from your Audit

Reporting the Audit

Final Thoughts

References

Quality Assurance in a Microbiology Laboratory

by Christophe Barcella

Introduction

Quality Management, QA and QC Principles

Quality Management

Quality System

Quality Assurance

Quality Control

Laboratory Quality Manual

Laboratory Staff Qualifications and Training

Training Policy

Job Description

Curriculum Vitae

Staff Training Records

Laboratory Environment

General

Air Ventilation

Lab Sanitation and Environment Monitoring

Environmental Hygiene and Health

Protective Equipment

Standard Operating Procedures, Methods and Protocols

Development, Review and Approval of SOPs

New Method Development, Validation and Amendment

Quality Attributes for a New Method

Laboratory Notebooks, Log Books and Records

Minimum Acceptable Procedures for Laboratory Notebooks

Review of Test Results

Electronic Records

Information Technology and Computer Systems Validation

Definition of Hardware and Software

Computer Security and Backups

Computer Systems Validation (CSV)

Archiving Requirements

Archiving Physical Facilities

Archiving Personnel

Archiving Electronic Records

Format of Archived Materials

Laboratory Test Samples and Preserved Wet Materials

Duration of the Archive

Reference Standards and Samples

Reference Standards for Microbiological Testing

Reference Standards Storage, Handling and Labeling

Standard References Records

Microbiological Reference Strains

Management of Samples

Solutions, Reagents and Culture Media

Reagent General Specifications

Reagent Tracking

Reagent Solutions

Quality Control of Culture Media

Instruments and Equipment

Equipment Installation and Qualification

Equipment Operations

Equipment Calibration and Maintenance

Glassware and Volumetric Micropipettes

Glassware Grades

Micropipettors

Laboratory QA Assessments/Audits & External Quality Assurance

QA Audit Methodology

External Quality Assessment (EQA)

Internal Quality Assessment (IQA)

Conclusion

References

Part: 3 Measuring and Testing for Microorganisms

Environmental Monitoring

by Tim Sandle

Introduction

Cleanrooms

Isolators

Cleanroom Classification

Physical Parameters

Air-patterns and Air-Movement

Airflows

Air Changes

Clean-up Times (Recovery Rate Test)

Positive Pressure

HEPA Filters

Temperature, Humidity, Lighting and Room Design

Microbiological Environmental Monitoring

Viable Monitoring Methods

Swabs

Contact Plates

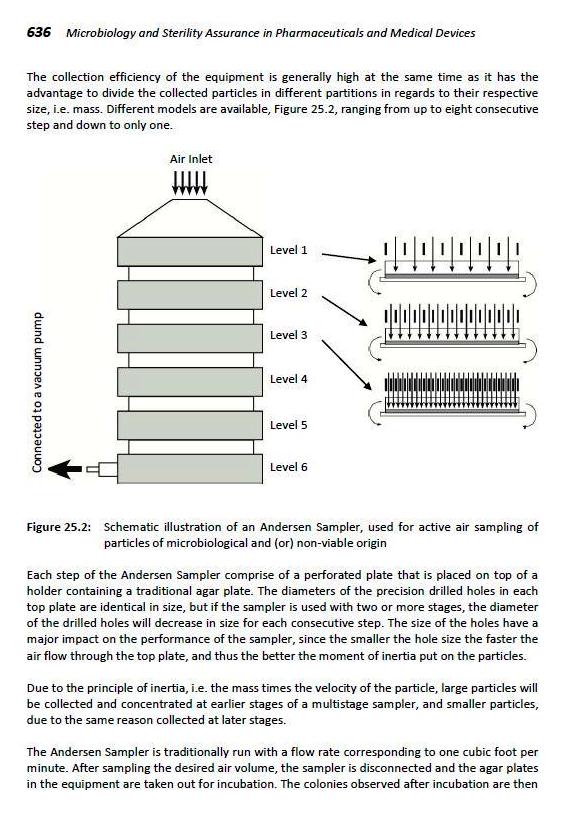

Active Air Monitoring

Types of Active Air-Sampler

Settle Plates

Non-viable Monitoring Methods

Establishing an Environmental Monitoring Programme

Sampling Plans

Sample Frequencies

Sample Limits

Personnel

Aseptic Technique

Other Cleanroom Disciplines

Clothing

Cleaning

Summary

References

Microbial Content Testing of Pharmaceutical and Biotechnologically Derived Products

by Dilip Ashtekar and Tim Sandle

Introduction

General Methods for the Quantitative Determination of Viable Count

Membrane Filtration

Pour Plate

Surface Spread plate

Most Probable Number

Evaluation of Results by Various Enumeration Methods

Points to Consider for Counting CFU

Rounding and Averaging

Significant Figures

Countable Range

Statistical Errors from Low Counts

Dilutions

Replicate Plate Counts

Consideration of Performing of Replicate Samples in Place of Testing One Large Sample

Selection of Method for the Enumeration of Microbial Count

Estimating Number of Micro-Organisms in Suspension for Use in Bioburden

Validation or Suitability Test for MLT

Bioburden Testing

Bioburden Test Method Validation

Validation Requirements

Microbial Limit test (MLT)

A1: The TAMC Test

Reporting of Enumeration Test Results

Spreaders

Suitability of the Enumeration Method in the Presence of Product

Test for Specified Organisms

Applied Aspects of Bioburden Testing

Method Limitations

Sample Expiry

Incubation Parameters

Influencing Factors

Staff Proficiency Training

Plate Counting

Pour Plates

Conclusions

References

Bacterial Endotoxins Test

by Masakazu Tsuchiya

Introduction

History of Bacterial Endotoxins Test

Endotoxin

Structure and Biological Activity of Endotoxin

Stability of Endotoxin

Standard Endotoxin

Variability of Potency of Daily RSE Dilutions

Limulus Amebocyte Lysate

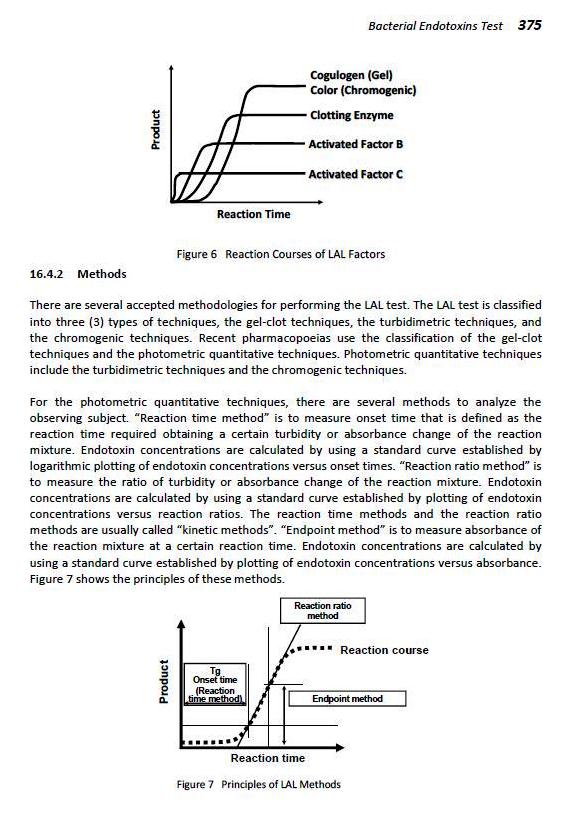

Principle

Methods

Reactivity of LAL

Pyrogenicity and LAL Test

Bacterial Endotoxins Test in Pharmacopoeias

Validation of Bacterial Endotoxins Test

Practical Suggestions for the Bacterial Endotoxins Test

Uncertainty of Bacterial Endotoxins Test

Interfering Factors

Contamination

Removal of Endotoxin/β-Glucan

Robust LAL Methods Using an Archived Standard Curve

Conclusion

References

Acknowledgment

Appendix A (Example of Standard Operating Procedure for Gel-Clot Method)

Antimicrobial Effectiveness Testing

by Scott V. W. Sutton

Introduction

The Purpose of the AET

What the Test Means

USP

Pharm Eur

Development of the USP Test

USPXVIII - The Original Test

USP XIX - Refinements

USP XX, XXI and XXII – Little Activity

USP 23, 24 and 25 - Reducing Variability

USP 23, 24 and 25 - Harmonization?

Demonstration of Method Suitability

Importance of Preservative Neutralization

Development of USP <1227>

Method Suitability for Quantitative Studies

Other considerations in preservation

Container/Closure

In-use Testing

Investigations

Lab Investigations

Specific Considerations for AET

Summary/Conclusions

References

Monitoring of Microbiological Quality Attributes of Water for Pharmaceutical Use

by Dilip Ashtekar

Introduction

Water Types

Regulatory Requirements

Water System Description

Prefiltration

Activated Carbon

Softeners

Deionization

Reverse Osmosis

Ultrafiltration

Ultraviolet Light

Ozone

Final Filtration

Distillation

Storage Tanks

Distribution Systems

Water System Validation

Installation Qualification

System Characterization Studies and Testing

Operational Qualification

Performance Qualification

Phase I PQ Testing

Phase II PQ Testing

Post-Validation Monitoring

Water System Monitoring

Sampling and Frequency of Monitoring

Sample Collection and Testing

Alert and Action Levels

Response to Confirmed Alert and Action Level Excursions

Water Data Trending Requirements

Conclusions

References

Investigation of Microbiological Data Deviations

by Mónica Lagomarsino

Introduction

Microbiological Data Deviations

Objectives of the Investigation

Acceptance Criteria

General Process for the Investigation

Laboratory Investigation

Full-Scale Investigation

A Case Study

Conclusion

References

Recommended Bibliography

Alternative Microbiological Methods and New Pharmaceutical Microbiology Curriculum

by Claudio D. Denoya

Introduction

A “Rapid” History of Microbiology

Today’s Microbiology: The Fundamentals of “Traditional” Microbiology

The New Microbiological Technology Wave for the QC Lab: Alternative and Rapid

Microbiological Method (ARMMs)

Metabolic or Growth Based Technologies

Viability Based Technologies

Technologies Based on Cell Component Analysis

ARMMs and the Pharmaceutical Industry

AMM, PAT, and Regulatory Status

Microbiology Curricula

The Skill Sets of a Pharmaceutical Quality Control (QC) Microbiologist

Curricula Surveys

The Disparity between the Tertiary Microbiology Curricula and the Needs of the

Pharmaceutical Industry QC Microbiologist

An Interesting Step Forward: The United States Professional Science Master''''''''s

Programs

Conclusions and Recommendations

Acknowledgments

References

The Implementation of Rapid Microbiological Methods

by Michael J. Miller

Microbiology Trapped In the 19th Century

New Technologies for Pharmaceutical Manufacturing

An Introduction to Rapid Microbiological Methods

RMM Applications

Strategy for Implementation

Validating Rapid Microbiological Methods

Initial Activities

The Validation Strategy

Risk Assessment

Validation Master Plan (VMP)

User Requirements Specifications (URS)

Design Qualification (DQ)

Supplier Assessment/Audit

Functional Design Specifications (FDS)

Requirements Traceability Matrix (RTM)

Training and SOPs

The Test Plan

Installation Qualification (IQ)

Operational Qualification (OQ)

Validation Criteria for Quantitative Tests

Validation Criteria for Qualitative Tests

Validation Criteria for Microbial Identification Tests

Performance Qualification (PQ)

Validation Summary Report

Implementation and Secondary Site Qualification

RMMS and the Regulatory Environment

FDA Perspectives

Pharmaceutical cGMP’s for the 21st Century: A Risk-Based Approach

Process Analytical Technology (PAT)

Sterile Drug Products Produced by Aseptic Processing – cGMP

RMM’s for Sterility Testing of Cellular and Gene Therapy Products

Encouragement from FDA’s Microbiology Review and Compliance Staff

Strategies for Implementing RMMs with the FDA

EMA Perspectives

EMA Revised Variations Regulation

PDA Forum on Implementing RMMs in Europe

Type Variations

Scientific Advice

RMM Validation

The EMA PAT Team

Changing Acceptance Levels and Specifications

Regulatory Summary

Developing a Business Case for RMMS

Where Can Savings Come From?

Creating an Economic Analysis

Operating Costs Associated with the Conventional Method

Operating and Investment Costs Associated with the RMM

Cost Savings/Cost Avoidances Associated with the RMM

Return on Investment (ROI)

Payback Period (PP)

Net Present Value (NPV)

Chapter Summary

Acknowledgement

References

Risk Management in Pharmaceutical Microbiology

by Tim Sandle

Introduction to Risk Assessment and Risk Management Process

Regulatory Views and Guidelines on Risk Management

The Basics of Risk Assessment

Advantages and Disadvantages of Risk Assessment

Risk Assessment and Risk Management Methodologies

HACCP: Risk Based Approach in Environmental Monitoring

Case Study 1

Deconstructing the Process

Route Map

Identification of Hazards

Process Flow

Environmental Monitoring

Risk Assessment

Perform a Simulation

Evaluation

FMEA - Risk Based Approach in Sterility Testing

Case Study 2

Sterility Testing Isolator: The Case Study

Description of the System

Application

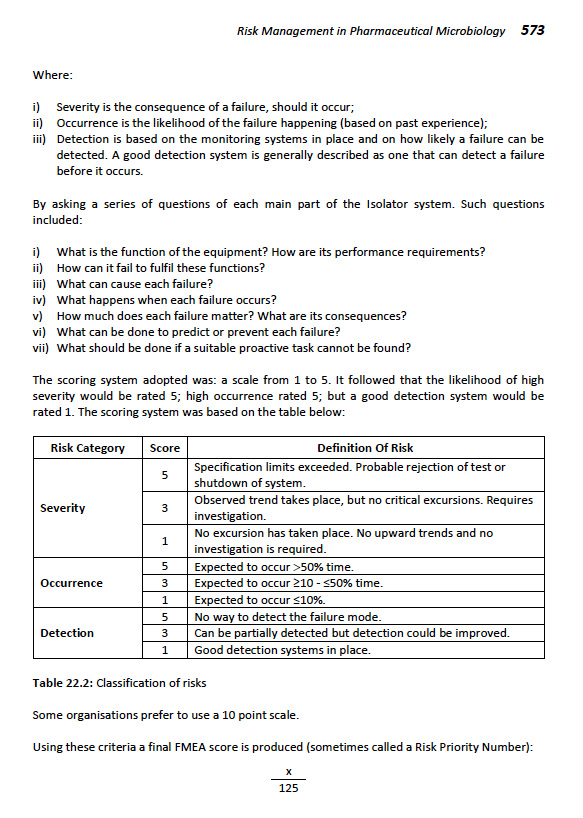

The FMEA Study on the Sterility Testing Isolator System

Designing the FMEA Scheme

The FMEA Exercise

Examination 1: The Isolator Room

Examination 2: Potential of Sanitisation Cycle Failure

Examination 3: Frequency of Isolator Sanitisations

Examination 4: Compromise of Isolator Integrity

Examination 5: Connection of Transfer Isolator to Main Isolator and

Transfer-in / out of Material

Examination 6: Incomplete Transfer Isolator Sanitisation

Examination 7: Failure of a Daily, Weekly or Six-monthly Physical

Parameter - HEPA filters / Pressure Leaks to Canopy

Examination 8: Pressure Leaks to Gloves

Summary

Other Available Tools

Ishikawa or Fishbone Diagrams

Risk Ranking

Risk Filtering

Risk Modelling

Contradiction Tables or Matrix

Conclusion: The benefits of Risk management

References

Part: 4 Sterilization and Sterility Assurance

Sterility

by Edward C. Tidswell

Introduction

Origins of Sterilization

The Microbial Challenge

Consequences of Non-Sterility and Lack of Asepsis

What Does Sterile Mean and Can We Test It?

Conclusion

References

Process Selection for Sterile Products

by James Agalloco

Introduction

Terminal Sterilization and Adjunct Processing

Aseptic Processing

Conclusion

References

Microbial Contamination Control in Pharmaceutical Manufacturing

by Matts Ramstorp

Pharmaceutical Cleanrooms and Clean Zones

Introduction

The Use of Proper Hygiene

The Historic Development of Microbiology

Aseptic Techniques

Production of Medicinal Products

Why is Pharmaceutical Production Different from Microelectronics?

Classification of Pharmaceutical Cleanrooms

Good Manufacturing Practice (GMP)

Design of Pharmaceutical Cleanrooms

How to Proceed with the Design of a Pharmaceutical Cleanroom

Cleanroom Cleanliness

Pharmaceutical Cleanroom Classification

Measuring Cleanliness within Pharmaceutical Cleanrooms

Particle Counting

Microbial Monitoring

Analysis of Microbiological Contaminants in the Air

Sampling of Microorganisms

Sampling of Microorganisms in the Air of a Cleanroom

The Andersen Sampler

Slit-to-Agar-Sampler

The RCS-Sampler

Liquid Impinger

Surface Sampling

Microbiological Contaminants and GMP

Pharmaceutical Cleanroom Ventilations Systems

Conventional Ventilated Cleanrooms

Unidirectional Flow Cleanrooms

Ventilation Filter for Pharmaceutical Cleanrooms

Cleanrooms and Clean Zones

Working in Clean Zones

Pharmaceutical Cleanroom Production Systems

Production using Terminal Sterilization

Aseptic Production

Cleaning and Disinfection of a Pharmaceutical Cleanroom

Introduction

What is the Purpose of Cleaning?

What is Cleaning?

How to Work with Preventive Cleaning

Active Cleaning

Classification of Surfaces in a Cleanroom

Cleaning Program for Cleanrooms

Example of a Cleaning Program

How to Analyse and Control Cleaning

Cleaning Techniques

Cleaning Methods

Dry Cleaning Methods

Wet Cleaning Methods

Cleaning Solution

The Zinner Circle

Disinfection

Potential Risk Factors Associated with Cleanroom Decontamination

Standards and Practices

Cleanroom Garments

Introduction

What is the Purpose of the Cleanroom Garment?

Garment Systems

Single-use versus Washable Garments

Choice of Material

Comfort

Construction of Garment Systems

The EU GMP and Cleanroom Garment Systems

Using Cleanroom Garments

Clothing, Personal Items and Underwear

Processing of Clothing and Change Frequency

Risk Factors Associated With Cleanroom Clothing

Conclusions

Personal Hygiene and Personal Responsibility

Introduction

Humans as Particle Generators

Particles and Fibres

The Normal Flora of Man

Good Manufacturing Practice in Relation to Personnel

Personal Hygiene

The Interconnection between Personnel and the Process

Contamination Hazards Connected to Personnel

General Rules when Working in Cleanrooms and other Controlled Environments

Acknowledgement

References

Aseptic Process Simulations/Media Fills

by Marco Budini and Francesco Boschi

Introduction

Documentation

Media Selection

Frequency and Number of Runs

Size and Duration of Runs

Line Speed and Container Size

Closure Type

Process/Line Configuration and Set-up

Fill Volume

Number of Persons and Activities

Interventions

Line Clearance

Environmental and Personnel Monitoring

Other Worst Case Scenarios

Cleaning after Process Simulation

Incubation and Inspection of Filled Units

Growth Promotion Test

Interpretation of Results – Acceptance Criteria

Invalidation and Abortion of Process Simulation Runs

Investigation of Process Simulation Contaminations/Failures

Conclusions

References

Biological Indicators for Sterilization

by Russ Nyberg

Description

Performance Qualification of Biological Indicators

BI Use in Parenteral Product Loads

Use of a Process Challenge Device (PCD)

Selection of BIs

Contracting for 3rd Party D-Value Testing

Equipment

Test Method Used

Recovery Media

Technique and Lab Utensils/Personnel

Rapid Read-out Biological Indicators

Conclusion

References

Moist Heat Sterilization

by Michael Sadowski

Introduction

Sterile Products

History of Sterilization with Heat

Mechanisms of Spore Heat Resistance And Inactivation

Inactivation of Spores Using Moist Heat Sterilization Processes

Use of Semilogarithmic Survivor Curve Model for Characterizing and Predicting Microbiological Inactivation

Pharmaceutical Products

Selection of a Moist Heat Sterilization Process Type

Saturated Steam Sterilization Processes

Gravity Displacement Processes

Pre-vacuum Processes

Air Overpressure Processes

Steam/Air Mixture Processes (SAM)

Superheated Water Air Overpressure Processes

Product or Item Loading Patterns

Biological Indicators for the Development and Qualification of Moist Heat Sterilization Processes

Determination of The Hardest to Sterilize Solution Formulation or Item/Component

The Liquid Products Master Solution Approach

The Process Challenge Device (PCD) Approach for Porous/Hard Goods

Determination of Hardest To Sterilize Locations or Cold Spots Used For Penetration Probes

Use of Chemical Indicators

Development Moist Heat Sterilization Processes

Development of the Sterilization Process Heat Up/Conditioning Phase

Development of the Sterilization Process Cooling/Drying Phase

Development of the Exposure Phase

Determination of the Minimum Physical Lethality Value

Minimum Physical Lethality Values Prescribed in Regulatory Standards

Minimum Physical Lethality Values Required for the Overkill Cycle Design Approach

Determination of Minimum Physical Lethality Values for the Product Specific Approach

Determination of Exposure Time to Meet Minimum Physical Lethality Requirements

Use of Biological Lethality in the Determination of Exposure Time

Use of the Fractional Exposure Approach in the Determination of Exposure Time

Validation of The Moist Heat Sterilization Process

Installation Qualification

Operational Qualification

Pre-vacuum Sterilizer Vacuum Leak Rate Test

Steam Penetration or Bowie Dick Type Test

Steam Quality Tests

Performance Qualification

Use of Physical Lethality in the Qualification of Moist Heat Sterilization Processes

Use of Biological Lethality in the Qualification of Moist Heat Sterilization Processes

Routine Monitoring and Control of the Moist Heat Sterilization Process

Preventive and Unplanned Maintenance

Calibration Program

Ongoing Sterilizer and Utility System Functionality Tests

Product and Process Change Control

Sterile Product Release Process

Bioburden Testing

Sterilizer Functionality

Sterilization Cycle Parameters

Chemical Indicator and Biological Indicator Results

The Sterility Test

Parametric Release

Conclusion

Acknowledgement

References

Sterilization and Depyrogenation by Dry Heat

by Madhu Raju Saghee and Gary R. Mitchel

Introduction

Functions of Dry Heat

Thermodynamical Aspects of Heat Transfer in Dry Heat Processes

Destruction of Microorganisms and Endotoxins by Dry Heat

Spectrum of Activity on Microbial Populations

Effect of Microbial Water Content in Dry Heat Sterilization Processes

Effect of Temperature and Time

Destruction of Endotoxins

Types of Dry Heat Sterilization/Depyrogenation Processes

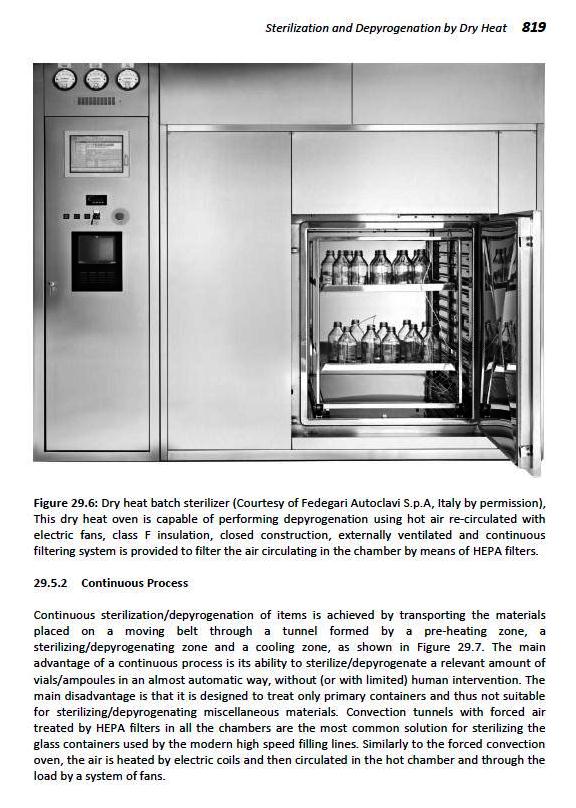

Batch Process

Continuous Process

Validation and Ongoing Control

Temperature Measurement Errors

Validation Approach

Installation Qualification

Operational Qualification

Performance Qualification

Routine Monitoring and Control

Conclusion

References

Acknowledgements

Appendix A (Example of an outline for an Installation Qualification protocol)

Appendix B (Example of an outline for Operational and Performance Qualification protocols)

Radiation Sterilization

by Mark A. Seybold and John A. Williams

Introduction

History of Radiation Sterilization

Types of Radiation Sterilization

Gamma Sterilization

Electron Beam Sterilization

X-Ray Sterilization

Radiation Sterilization Applications

Microbial Inactivation

Mode of Action

Microbial Resistance to Ionizing Radiation

Radiation Resistance Factors

Environmental Factors

Organism Characteristics

Inactivation Kinetics

Validation

Installation Qualification

Operational Qualification

Performance Qualification

Microbiological Validation of Radiation Sterilization Processes

Dose Setting

Method 1

Method 2

Method VDmax

Materials Qualification

Process Validation

Routine Monitoring And Control

Maintaining Process Effectiveness

Biorburden Monitoring Program

Dose Audits

Radiation Equipment

Conclusions

References

Sterilization by Filtration

by Maik W. Jornitz and Theodore H. Meltzer

Introduction to Sterilizing Filtration

Filtration Parameters

Contamination Removal

Rate of Flow

Total Throughput

Unspecific Adsorption

Filter Types

Filter Materials

Filter Construction

Filter Validation

Filter Integrity Testing

Bubble Point Test

Diffusion Test

Pressure Hold Test

Water Intrusion Test

Product Wet Integrity Testing

Filtration Applications

Liquids

Solvent (API) Filtration

Ophthalmics Filtration

Cell Culture Media

Buffer Filtration

Gases

Fermentor Inlet Air

Fermentor Off-Gas

Vent Filters on Tanks

Autoclave and Lyophilizer Vent Filter

Filtration of Service Gases

References

Sterilization by Ethylene Oxide

by Gerry A. O’Dell

Introduction

Factors Affecting the Lethality of EO Sterilization

Gas Concentration

Humidity/Moisture

Temperature

Inherent resistance of microorganisms

Conferred resistance

Combination of factors

The EO Sterilization Process

Preconditioning

Sterilization Cycle

Aeration

Product and Process Definition for EO Sterilization

Product definition

Process definition

EO Sterilization Validation

Installation Qualification

Operational Qualification

Performance Qualification

Microbiological PQ

Physical PQ

Routine monitoring of the EO sterilization process

Conventional Release

Parametric Release

Use of tests for sterility

Demonstrating the Ongoing Effectiveness of the EO Sterilization Process

Addressing changes (change control)

Process equivalence

Product adoption

Periodic requalification

Summary

References

Maintaining Sterility

by Michelle A. Luebke & Bonnie J. Heredia

Introduction to Maintaining Sterility

Medical Product Packaging System Development

Packaging Development Phase

Routine Manufacturing/In-Process Control Phase

Stability/Product Testing Phase

Microbiological Versus Physical Integrity Test Methods

Test Method Correlation

Direct Approach

Indirect Approach

Test Method Sensitivity

Test Method Validation

Method and Vendor Requirements

Validation Plan

Installation Qualification

Operational Qualification

Performance Qualification

Sterile Medical Product Classification

Medical Devices

Medical Devices - Sterile Designation

Medical Devices - Sterile Fluid Path Device Designation

Needleless Medical Devices

Drugs and Biologics

Sterile Barrier System Classification

Seals

Closures

Sterile Barrier Integrity Test Methods

Physical Methods

Visual Inspection

Bubble Test

Pressure/Vacuum Decay

Dye Test

Tracer Gas Leak Detection

Microbiological Methods

Microbial Challenge - Liquid Immersion

Microbial Challenge - Aerosolization

Static Aerosol Challenge

Dynamic Aerosol Challenge

Simulated Clinical Use Test Method

Miscellaneous Methods

Summary

References

Index