Content

CONTENTS

1 Fundamentals of Global GMP Requirements

by Atul Shirgaonkar

Introduction

What are GMPs

History and Evolution of GMPs

Major International GMPs

Quality Management

Product Quality Review

Quality Risk Management

GMP: Differences between US FDA and EU

Requirements

Conclusion

References

2 Effective CAPA Management for Optimal

Compliance

by Michael Hopper

Introduction

Examples of CAPA Issues

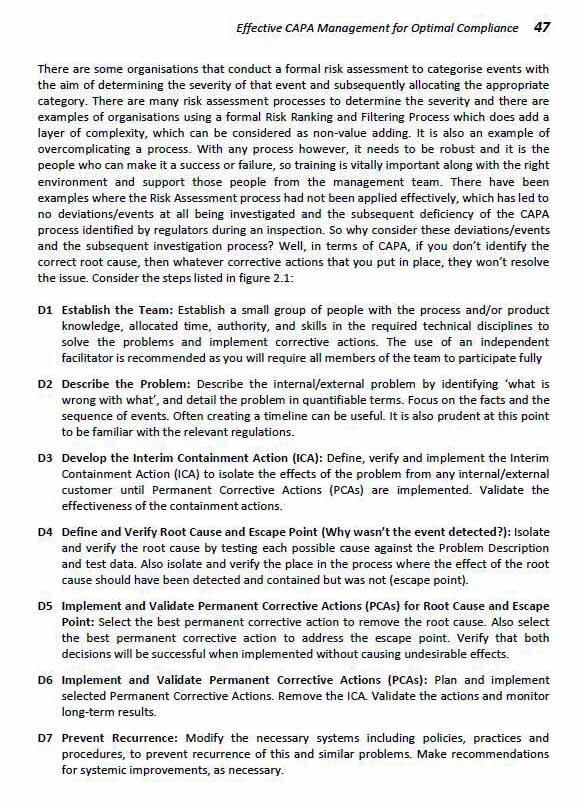

Global 8D

Human Error

Approaches to CAPA

Summary

References

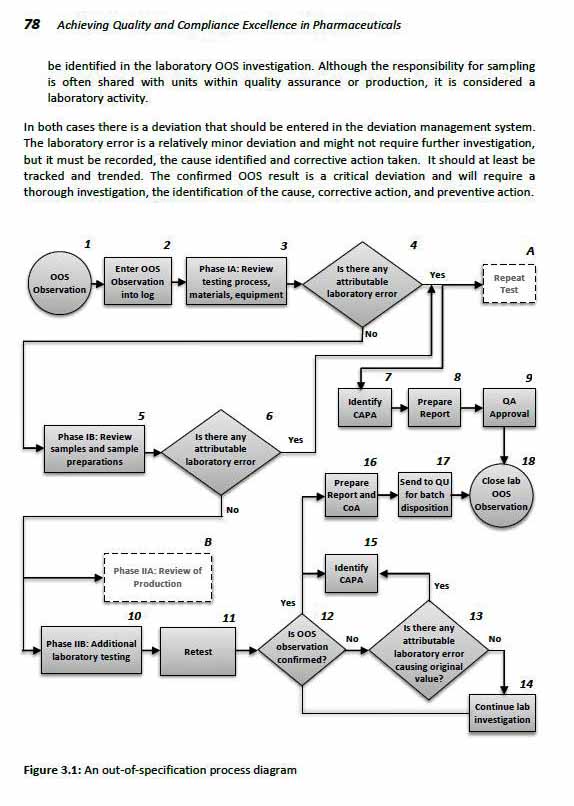

3 Laboratory Compliance and Handling Out-of-

Specification (OOS) Results in the Laboratory

by John Lanese and A.V. Prabhu

Laboratory Controls

Handling Out of Specification (OOS) Results

Phase I of the OOS Investigation

Phase II of the OOS Investigation

Conclusion

References

4 Effectively Incorporating Quality Risk

Management into Quality Systems

by Tim Sandle and Sanjit Singh Lamba

Introduction

Quality Systems

Guidelines

Anatomy of ICH Q9

Applying Quality Risk Management

The Basics of Risk Assessment

Risk Assessment Tools

The Integration of QRM into Some Process Quality

Systems

Advantages and Disadvantages of Risk Assessment

Conclusion

References

5 Monitoring and Controlling Process Drift for

Enhancing Quality

by Nandkumar Chodankar

Introduction

Definition of Process Drift

Chance Cause

Background of Process Development and Process

Validation

Process Variables (Identified Chance Cause)

Combined Effect of Variables

What Could be the Additional Causes for Process

Drift

Categorizing Process Drift

Approaches to Developing a Control Strategy

Steady State Concept

Development of Critical Strategy for Process

Modelling Control Design

PAT: A Tool for Online Process Control

Steps involved in API Manufacturing and Their

Control

Steps involved in Drug Product Manufacturing and

Their Control

Summary

References

6 Qualification and Validation

by Tim Sandle

Introduction

Regulations

History of Validation

Validations Concepts and Documentation

Risk Based Approaches to Validation

Re-Validation Requirements

Different Types of Validation: Case Studies

Conclusion

References

7 Process Validation

by Mark F. Witcher

Introduction

History of Manufacturing Controls & Process

Validation

Design Space - Defining and Describing the

Manufacturing Process

FDA''s 2011 Validation Paradigm

Product Lifecycle

The Role of QbD in Process Validation

Understanding the Process Validation Paradigm

Using the Process Validation Paradigm

Quality Risk Management (QRM) for Process

Validation

Legacy Products

Validation Master Plan (VMP)

References

8 Documents, Records, and Part 11 Compliance

by Janet Gough

Introduction

Documentation and Regulation

The Document Continuum

Features of Robust Systems

Part 11

Deciding to go Electronic

System Documentation

Maintaining Compliance and Inspection Readiness

References

9 Change Control and Management

by R. Raghunandanan

Introduction

Key Definitions

Categorization of Different Changes

Why Change Control

Regulatory Requirements

GMP Requirements

Business Requirements

Change Control Management Process

Documentation

Example of FDA Warning Letter

References

10 Deviation Management

by Alicia Tébar Pérez

Introduction

Deviations - Regulatory Framework

What Constitutes a Deviation

Deviation Management Flowchart

Deviations into the Quality System

Common Deficiencies Related to Poor Deviation

Management

Deviation Management from a Risk/Science Based

Perspective

Applying Risk Analysis to Deviation Management

Deviations and Knowledge Management for

Continuous Improvement

Advanced Tools for Deviation Management

and Reduction

Conclusions

Acknowledgements

References

11 Internal Quality Assessments/Self-Audits

by R. Raghunandanan

Introduction

Key Definitions

Why Internal Quality Audits

Regulatory Requirements

Who Carries Out Audits

Auditor Requisites

Auditing Process

Reporting and CAPA

Why Audits Fail

Need to Strengthen Internal Audit System

12 Designing an Effective GMP Training Program

by David Markovitz

Introduction

GMP Training is a Process

GMP Training - A Process to Ensure Compliance

Proper Preparation for Effective GMP Training

Conducting Effective GMP Training: Dos and Donts

for Success

Effective Followup Strategiesto GMP Training

Start with the Basics

Conclusion

13 Behavioural GMPS (bGxP®): A New Paradigm

in Compliance Management

by Brian Szukala

Introduction: Challenges Facing the Industry

Surviving in a World of ''Non-Compliance''

Origins of bGxP

The Concept of Behavioural Compliance

Drivers for Behavioural Change - PIMS Model

First Step in the Process - The ICE Audit

Human Error and bbCi

Sustaining the Change and Future Developments

in GxP

References

14 Supplier Quality Management

by Ajit Basrur and David Stephon

Introduction

Government Regulatory Drivers

Applicable Regulations/Guidelines

Supplier Controls

Sub Tier Suppliers

References

Key Terms

15 Understanding the United States Pharmacopeia

(USP)

by Robert D. Seltzer

Introduction

General Notices

Mandatory USP General Chapter Key Takeaways

Informative USP General Chapter Key Takeaways

Acknowledgements

References

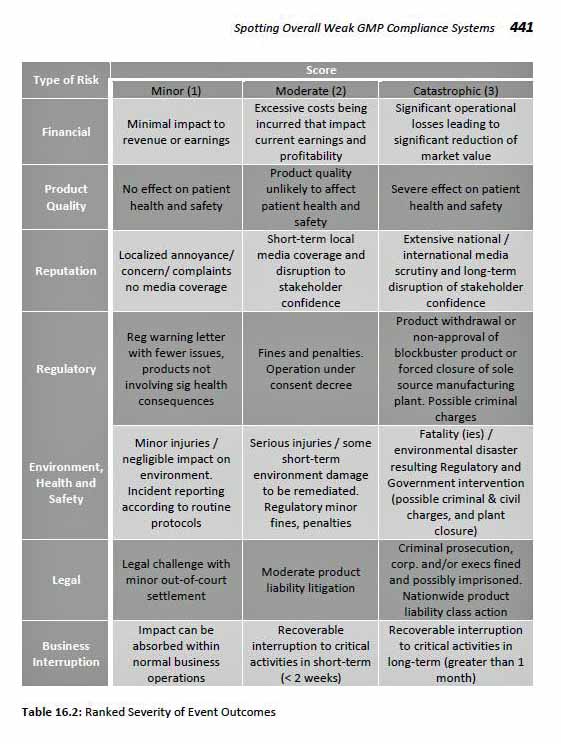

16 Spotting Overall Weak GMP Compliance

Systems

by Robert D. Seltzer

Introduction

Key Definitions, Fallacies in Logic and GMP

Literacy

Risk Categorized and Semi-Quantified

Trigger Events for Investigation, Remediation and

Corrective Action

Causes and Effects

Product Quality Complaints

Corrective Action Completeness and Effectiveness

Concluding Remarks and Examples

Acknowledgements

References

17 Meaningful Performance Metrics for

Compliance

by Roger Janczak

Overview of Performance Metrics

Principles of Establishing Performance Metrics for

Compliance

Compliance Metrics

Reviews, Scorecards and Dashboards

Other Considerations

References

18 Implementing ICH Q 10: A Pragmatic Approach

by Alok Ghosh and Nilanjana Basu

Introduction: What is ICH Q10

Key Messages of ICH Q10

Roles and Responsibilities of Senior Management

Product Lifecycle Covered by PQS

Continual Improvement

Enablers of PQS

Manufacturing Implementation & PQS

Conclusive Remarks

Acknowledgement

References

19 Compliance Aspects of APIs Manufacturing

by Richard Einig

Introduction

Quality Management and Personnel

Facilities, Equipment and Utilities

Production

Laboratory Control and Stability Studies

Conclusion

References

20 Compliance Aspects of Sterile Manufacturing

by Tim Sandle and Madhu Raju Saghee

Introduction

Sterility

Methods of Producing Sterile Products

A Brief History of Compliance Pertaining to Sterile

Products

Compliance Aspects of Sterile Manufacturing

Important Compliance Issues

Summary

References

21 Domestic and International U.S. Food and Drug

Administration (FDA) Inspections

by Robert D. Seltzer

Introduction

Types of Inspections

Inspections of Foreign Drug Manufacturers

Inspection Techniques

FDA Inspection Preparedness and Handling

Implications from FDA''s Admission to the PIC

Acknowledgements

References

22 Avoiding FDA Enforcement Actions: An

Optimal & Sustainable Compliance Program

by Areta Kupchyk

Introduction

FDAs Legal Authority

FDA Enforcement

Post Approval Requirements, Compliance,

and Enforcement

Other FDA Compliance and Enforcement Methods

Tools

Concusions and Recommendations

23 Developing a Master QMS Plan

by John E. Lincoln

Introduction

Development of "Quality" in the 21st Century

Master QMS Plan - Product Use Risk Based

Developing a Master QMS Plan

Quality Systems at US FDA and EU

Modern Quality Systems

A Pragmatic Framework for Building a Culture of

Compliance

Conclusion

24 Trends in cGMP Compliance

by Mitch Manning

Introduction

What are Trends in GMP Compliance

Why Identify GMP Compliance Trends

How to Identify and Use GMP Compliance Trends

Conclusion: Trends in GMP Compliance

References

Content

CONTENTS

1 Fundamentals of Global GMP Requirements

by Atul Shirgaonkar

Introduction

What are GMPs

History and Evolution of GMPs

Major International GMPs

Quality Management

Product Quality Review

Quality Risk Management

GMP: Differences between US FDA and EU Requirements

Conclusion

References

2 Effective CAPA Management for Optimal Compliance

by Michael Hopper

Introduction

Examples of CAPA Issues

Global 8D

Human Error

Approaches to CAPA

Summary

References

3 Laboratory Compliance and Handling Out-of-Specification (OOS) Results in the Laboratory

by John Lanese and A.V. Prabhu

Laboratory Controls

Handling Out of Specification (OOS) Results

Phase I of the OOS Investigation

Phase II of the OOS Investigation

Conclusion

References

4 Effectively Incorporating Quality Risk Management into Quality Systems

by Tim Sandle and Sanjit Singh Lamba

Introduction

Quality Systems

Guidelines

Anatomy of ICH Q9

Applying Quality Risk Management

The Basics of Risk Assessment

Risk Assessment Tools

The Integration of QRM into Some Process Quality Systems

Advantages and Disadvantages of Risk Assessment

Conclusion

References

5 Monitoring and Controlling Process Drift for Enhancing Quality

by Nandkumar Chodankar

Introduction

Definition of Process Drift

Chance Cause

Background of Process Development and Process Validation

Process Variables (Identified Chance Cause)

Combined Effect of Variables

What Could be the Additional Causes for Process Drift

Categorizing Process Drift

Approaches to Developing a Control Strategy

Steady State Concept

Development of Critical Strategy for Process Modelling Control Design

PAT: A Tool for Online Process Control

Steps involved in API Manufacturing and Their Control

Steps involved in Drug Product Manufacturing and Their Control

Summary

References

6 Qualification and Validation

by Tim Sandle

Introduction

Regulations

History of Validation

Validations Concepts and Documentation

Risk Based Approaches to Validation

Re-Validation Requirements

Different Types of Validation: Case Studies

Conclusion

References

7 Process Validation

by Mark F. Witcher

Introduction

History of Manufacturing Controls & Process Validation

Design Space - Defining and Describing the Manufacturing Process

FDA's 2011 Validation Paradigm

Product Lifecycle

The Role of QbD in Process Validation

Understanding the Process Validation Paradigm

Using the Process Validation Paradigm

Quality Risk Management (QRM) for Process Validation

Legacy Products

Validation Master Plan (VMP)

References

8 Documents, Records, and Part 11 Compliance

by Janet Gough

Introduction

Documentation and Regulation

The Document Continuum

Features of Robust Systems

Part 11

Deciding to go Electronic

System Documentation

Maintaining Compliance and Inspection Readiness

References

9 Change Control and Management

by R. Raghunandanan

Introduction

Key Definitions

Categorization of Different Changes

Why Change Control

Regulatory Requirements

GMP Requirements

Business Requirements

Change Control Management Process

Documentation

Example of FDA Warning Letter

References

10 Deviation Management

by Alicia Tébar Pérez

Introduction

Deviations - Regulatory Framework

What Constitutes a Deviation

Deviation Management Flowchart

Deviations into the Quality System

Common Deficiencies Related to Poor Deviation Management

Deviation Management from a Risk/Science Based Perspective

Applying Risk Analysis to Deviation Management

Deviations and Knowledge Management for Continuous Improvement

Advanced Tools for Deviation Management and Reduction

Conclusions

Acknowledgements

References

11 Internal Quality Assessments/Self-Audits

by R. Raghunandanan

Introduction

Key Definitions

Why Internal Quality Audits

Regulatory Requirements

Who Carries Out Audits

Auditor Requisites

Auditing Process

Reporting and CAPA

Why Audits Fail

Need to Strengthen Internal Audit System

12 Designing an Effective GMP Training Program

by David Markovitz

Introduction

GMP Training is a Process

GMP Training - A Process to Ensure Compliance

Proper Preparation for Effective GMP Training

Conducting Effective GMP Training: Dos and Donts for Success

Effective Followup Strategiesto GMP Training

Start with the Basics

Conclusion

13 Behavioural GMPS (bGxP®): A New Paradigm in Compliance Management

by Brian Szukala

Introduction: Challenges Facing the Industry

Surviving in a World of ''Non-Compliance''

Origins of bGxP

The Concept of Behavioural Compliance

Drivers for Behavioural Change - PIMS Model

First Step in the Process - The ICE Audit

Human Error and bbCi

Sustaining the Change and Future Developments in GxP

References

14 Supplier Quality Management

by Ajit Basrur and David Stephon

Introduction

Government Regulatory Drivers

Applicable Regulations/Guidelines

Supplier Controls

Sub Tier Suppliers

References

Key Terms

15 Understanding the United States Pharmacopeia (USP)

by Robert D. Seltzer

Introduction

General Notices

Mandatory USP General Chapter Key Takeaways

Informative USP General Chapter Key Takeaways

Acknowledgements

References

16 Spotting Overall Weak GMP Compliance Systems

by Robert D. Seltzer

Introduction

Key Definitions, Fallacies in Logic and GMP Literacy

Risk Categorized and Semi-Quantified

Trigger Events for Investigation, Remediation and Corrective Action

Causes and Effects

Product Quality Complaints

Corrective Action Completeness and Effectiveness

Concluding Remarks and Examples

Acknowledgements

References

17 Meaningful Performance Metrics for Compliance

by Roger Janczak

Overview of Performance Metrics

Principles of Establishing Performance Metrics for Compliance

Compliance Metrics

Reviews, Scorecards and Dashboards

Other Considerations

References

18 Implementing ICH Q 10: A Pragmatic Approach

by Alok Ghosh and Nilanjana Basu

Introduction: What is ICH Q10

Key Messages of ICH Q10

Roles and Responsibilities of Senior Management

Product Lifecycle Covered by PQS

Continual Improvement

Enablers of PQS

Manufacturing Implementation & PQS

Conclusive Remarks

Acknowledgement

References

19 Compliance Aspects of APIs Manufacturing

by Richard Einig

Introduction

Quality Management and Personnel

Facilities, Equipment and Utilities

Production

Laboratory Control and Stability Studies

Conclusion

References

20 Compliance Aspects of Sterile Manufacturing

by Tim Sandle and Madhu Raju Saghee

Introduction

Sterility

Methods of Producing Sterile Products

A Brief History of Compliance Pertaining to Sterile Products

Compliance Aspects of Sterile Manufacturing

Important Compliance Issues

Summary

References

21 Domestic and International U.S. Food and Drug Administration (FDA) Inspections

by Robert D. Seltzer

Introduction

Types of Inspections

Inspections of Foreign Drug Manufacturers

Inspection Techniques

FDA Inspection Preparedness and Handling

Implications from FDA''s Admission to the PIC

Acknowledgements

References

22 Avoiding FDA Enforcement Actions: An Optimal & Sustainable Compliance Program

by Areta Kupchyk

Introduction

FDAs Legal Authority

FDA Enforcement

Post Approval Requirements, Compliance, and Enforcement

Other FDA Compliance and Enforcement Methods Tools

Concusions and Recommendations

23 Developing a Master QMS Plan

by John E. Lincoln

Introduction

Development of "Quality" in the 21st Century

Master QMS Plan - Product Use Risk Based

Developing a Master QMS Plan

Quality Systems at US FDA and EU

Modern Quality Systems

A Pragmatic Framework for Building a Culture of Compliance

Conclusion

24 Trends in cGMP Compliance

by Mitch Manning

Introduction

What are Trends in GMP Compliance

Why Identify GMP Compliance Trends

How to Identify and Use GMP Compliance Trends

Conclusion: Trends in GMP Compliance

References